Abrisa Technologies' Heat Strengthened & Tempered Glass Enhances Safety & Strength Characteristics

Heat strengthened glass from Abrisa Technologies is physically and thermally stronger than conventional glass, generally twice as strong as annealed glass. The safety characteristics also improve the bending strength over standard glass.

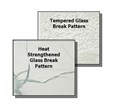

The heat strengthening process is utilized when a full temper of the glass substrate is not possible due to the thickness, size, or low thermal expansion rate of the glass substrate material. The heat strengthening process does not produce a full “dicing” pattern when the glass is broken, as is the case with glass that has been tempered. Fully tempered glass is typically four to six times stronger than annealed glass.

The primary difference between heat strengthened and heat tempered glass is the residual stress in the edge and glass surface, fully tempered glass is rated above 65 MPa (9,427 psi) in pressure resistance and heat strengthened glass is rated between 50 and 55 MPa (5801 and 7,977 psi).

The optical quality of the glass may be compromised to the extent that you see the tempering/quenching pattern when viewed through a polarizer. The cosmetics and flatness are also affected by the strengthening process; typically at 120/80 SD or at best 80/50 depending upon the size of the part.

Heat strengthening of glass is available in sizes of 168” x 96” (4,367.2 mm x 2,438.4 mm). This process can be done on glass with a minimal thickness of 1/8” (3.175 mm) and a maximum thickness of 1/2” (12.7 mm), (1” or 25.4 mm thick for smaller parts – up to 32”x 25” or 812.8 mm x 635 mm). In the heat strengthening process, the glass substrate is processed similar to a fully tempered part, except that the temperature and cycle times, along with the quenching parameters are varied.

Heat tempering of glass is available in sizes of 160” x 92” (4,064 mm x 2,336.8 mm). This process can be done on glass with a minimal thickness of 1/8” (3.175 mm) and a maximum thickness of 1/2” (12.7 mm), (1” thick for smaller parts – up to 30” x 24” or 762 mm x 609.6 mm). In the heat tempering process, the glass substrate is placed onto a roller table and then it goes through a furnace, heating up the glass above its annealing point up to about 720°C in some cases. The glass is then quickly cooled (quenched) with forced air drafts.

Typical applications for heat strengthened glass include: lighting fixture lenses, small cover lenses such as MR16s, PR20s, PR30s, and alike, where parts are not required to break into small shards based on the application.

Typical applications for heat tempered glass include: display cover lenses, decorative glass sheets and similar uses where the parts can be above 240°C and where public safety is crucial. If there is a high intensity light source behind the heat treated glass and the glass is in an application that the part needs to dice into small shards when broken, then the glass should be fully tempered.

Heat tempered and strengthened glass can also undergo various glass fabrication processes such as cutting, drilling, polishing, and edge work, however; these processes must occur prior to the strengthening or tempering process as damage and breakage can occur due to the stress in the glass as a result of the toughening process.

Abrisa Technologies processes comply with many industry quality standards, including ANSI, ASME, ASTM, ISO, MIL, JAN, and SAE.

About Abrisa Technologies:

Abrisa Technologies is headquartered in Santa Paula, California and is comprised of three divisions that provide precision optical products and services. The divisions include; Abrisa Industrial Glass, Inc., Sycamore Glass Components, and ZC&R Coatings for Optics. As a market leader in optical coatings and high quality precision glass fabrication, Abrisa Technologies is dedicated to providing premier customer service and cost-effective products that fit each customer’s exacting requirements.

SOURCE: Abrisa Technologies