LED Multichip and Chip on Board Packaging

As electronic products evolve technologically and the push for miniaturization continues, space constraints for electronics continue to be a concern for design engineers. Marktech Optoelectronics specializes in chip on board (COB) solution where many LED chips can be placed into a small amount of space offering many advantages to standard packaging. In addition to using COB technology for illumination purposes, emission and detection functions of a sensor application can be greatly enhanced. With the ability to pack more light emission or light detection chips into an area, performance of the circuit can greatly increase.

Buy it Now Through Digi-Key

Visit Digi-key to immediately buy Marktech LED Emitters and Detectors for use in your application.

Marktech for more than 25 years has been a technology leader specializing in LED chip processing and LED packaging. Our engineers can assist a customer with their application needs and offer solutions ranging from LED chips to finished packaging. We can manufacture LED Chip-on-Board assemblies incorporating single or multiple die configurations and wavelengths ranging from UV to Mid IR. Our technical and production engineers manage a vertically integrated manufacturing process of circuit layout, die wafer and chip processing, die attachment and finished product assembly. Throughout all of our processes, the highest levels of quality assurance are in place making sure that the initial design is carried through the entire process.

As experts in the field of LED emission and detection, Marktech can provide complex chip on board solutions which incorporate both emission and detection functions into one custom assembly. Stare of the art assembly, test and measurement equipment includes PL mapping, Die sorting, Zinc Diffusion…..

LED Chip on Board

Medical instrumentation is one business sector that benefits greatly from LED COB packaging. In applications like a medical endoscope for example, an illumination ring is needed on the end of a very narrow instrument. A COB light ring is the only feasible solution to pack enough chips to illuminate the subject matter taking into consideration that the instrument is a very narrow diameter platform and usually will have additional functions such as imaging to compete with for the same real estate.

In addition to using COB technology for illumination purposes, emission and detection functions of a sensor application can be greatly enhanced. With the ability to pack more light emission or light detection chips into an area, performance of the circuit can greatly increase.

Advantages of Chip On Board (COB)

- Higher Lumen Density

- Precision Positioning

- Compact Size

- Improved Thermal Management

- Increased Reliability

- Design Flexibility

LED Chip on Board Technology

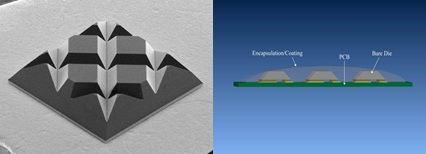

LED COB is defined as mounting an LED die(s), visible or infrared, directly to a printed circuit board as opposed to packaging the die in one of the standard options such as Surface Mount or Through Hole LED type packages. Depending on the chip type and structure, there are a few ways to properly attach or bond an LED chip to a pad of the PC board. Some of the more powerful chips available require a flux eutectic type attaching which limited vendors like Marktech can offer. Additional processes include wire bonding an electrical connection from the board to the LED chip and encapsulating the chip entirely to protect it from mechanical damage or contaminants.

CREE Direct Attach Die (No Wire Bonding Required – Lower Profile)

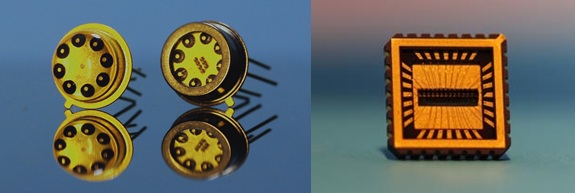

Multichip and Array Packaging

A variety of multichip packaging is also available through Marktech.