OLEDs Open up New Options in Display Technology

By: David Williams, <%=company%>

Contents

Creating an OLED display

Active and passive displays

Benefits of OLED

Recent advances

Applications

Organic light-emitting diode (OLED) displays are self-luminous devices in which organic thin films function as the light emitting material. Like conventional inorganic light-emitting diodes (LEDs), OLEDs require a low-drive voltage to produce bright visible light. Unlike discrete LEDs, which have crystalline origins, film-based OLED is an amorphous area emitter that can be lithographically patterned to produce flat-panel displays. In that regard, OLED technology is similar to that of liquid-crystal displays (LCDs). In contrast to LCDs, however, OLED displays are self-luminous and do not require backlights.

OLEDs have very low power requirements, for example the average operating power of a 2.5-in. diagonal full color display is 100 to 300 mW. On the order of 2 mm thick, OLED displays are bright and efficient. As a result, many see it as an emerging display technology, including market research agency Stanford Resources (San Jose, CA), which has put OLED on its hot technology list (see DappCon '00: OLEDs Move Into the Spotlight).

Creating an OLED display

First developed by researchers at Eastman Kodak Co. (Rochester, NY), OLED technology grew initially from research on organic electronic devices used in solar cells and electrophotography. The basic OLED cell structure consists of a stack of thin organic layers sandwiched between a transparent anode and a metallic cathode (see Figure 2). The organic layers comprise a hole-injection layer, a hole-transport layer, an emissive layer and an electron-transport layer. When an appropriate voltage (typically a few volts) is applied to the cell, the injected positive and negative charges recombine in the emissive layer to produce light (electroluminescence). The structure of the organic layers and the choice of anode and cathode are designed to optimize the recombination process in the emissive layer, thus maximizing the light output from the OLED device.

The organic thin films used in OLED devices can be classed as small molecule or macro polymer materials. Small molecule OLED films are applied using vapor sublimation in a vacuum chamber. In the case of polymers, solvent coating techniques such as spin coating are often used. Kodak focuses on small molecule technology, though we have development programs focusing on polymer devices.

By doping the emissive layer with a small amount of highly fluorescent molecules in a Kodak-proprietary method, researchers can enhance the electroluminescent efficiency and control color output.

Active and passive displays

OLED displays can be divided into two types: passive-matrix and active-matrix displays. The passive-matrix OLED display has a simple structure and is well suited for low-cost and low-information-content applications such as alphanumeric displays. The active-matrix OLED has an integrated electronic backplane as its substrate, and lends itself to high-resolution, high-information-content applications including videos and graphics.

A passive display is formed by providing an array of OLED pixels connected by intersecting anode and cathode conductors (see Figure 3). Kodak developed a relatively simple but unique method.

Advantages

•Photolithography prior to organic/cathode depositions

•High resolution possible

•Scaleable to large areas

Benefits of OLED

OLED offers numerous technology advantages over competing approaches for flat panel display:

- High brightness (>100 CD/M2)and contrast (>100:1)

- Unlimited viewing angles

- Full color displays in small molecule device; polymer-based technology is still working on full RGB

- Fast response in the microsecond range, better than 1000X faster than LCD technology

- Wide operating temperature range temperature range (-80° C to 80° C) for quick response displays in a variety of environments

- Low power consumption and operating voltage, maximizing battery life and minimizing heat and electric interference in electronic devices

- Light weight, compact, and thin, reducing the size and weight of devices that use displays

- Robust enough to use in portable devices such as cellular phones and personal digital assistants (PDAs)

- Economical

Recent advances

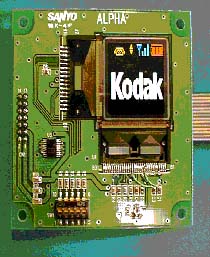

A new active-matrix, full-color, OLED display, originally demonstrated in October 1999 by Kodak and Sanyo Electric Co., will soon be used in digital cameras and many other portable electronics. Because of their superior viewing qualities, the full-color OLED displays will replace many conventional LCD screens. The initial 2.5-in. display prototypes have been scaled in the development laboratory to 5.5-in. sizes, which show good promise for applications beyond small appliances. more than 200 companies currently are conducting OLED research and development. eMagin Corp. (Hopewell Junction, NY) has developed microdisplays with pixel sizes less than 20 µm.

At the upcoming Society for Information Display meeting (SID; May 14-19; Long Beach, CA), Kodak and Sanyo will demonstrate active matrix displays, including electronic picture frame technology developed by Kodak and Weave Innovations Inc. that apply Kodak OLED materials and displays.

Applications

The technology is already at work in car audio units produced by Japan-based Pioneer Electronics, and Motorola has announced new wireless handsets with OLED displays. The display units will soon be ubiquitous in PDAs, digital cameras, video cameras, head-wearable displays, and automotive instrumentation. As the technology is refined, it holds possibilities in computer monitors, video displays, ultra-thin lighting panels, even flexible displays that could be rolled and unrolled.

Licensees for the Kodak small molecule technology include eMagin Corp. (Hopewell Junction, NY), Sanyo Electric Co., Pioneer Electronics, and TDK Corp. The company also supplies patented materials to its licensees.

About the author…

David Williams is general manager of display technology laboratory, Eastman Kodak Co., phone: 716-477-7575, e-mail: david.j.williams@kodak.com. He is responsible for research, development and commercialization of oled technology.